I’ve been planning for a while now to test the Arduino Uno and the GRBL CAM software with my HobbyCNC PRO board. I was certain it would interface, but I wasn’t keen on having to learn all the bits necessary to get it working.

- Upload/Flash the GRBL image to the UNO.

- Find a G-Code “Sender”.

- Understand the core GRBL configuration settings.

- Solder a test cable from the Ardunio to the HobbyCNC PRO

- Load a sample G-Code file and test

And I’ll be damned if it doesn’t work great! I still need to make adjustments for speed, acceleration, etc, test the motor enable, and lots more. But, for “right out of the box”, the damn thing worked!

Here’s a video of the initial test. So far only the Step and Direction for X, Y and Z-axis are connected. Most of the GRBL settings are “right out of the box”. This is all connected to a board on my Bed of Nails test jig.

I’ve still got to set parameters for steps per rotation and microstepping and such, as well as testing the stepper enable and limit switches and stuff. I plan to make a “shield” that will connect the Arduino to a 25pin female connector compatible with the HobbyCNC PRO pinouts.

You can find more information on the HobbyCNC PRO and Arduino page.

What is taking you so long??? A couple of years back I found Arduino GRBL Shield v0.7 which provided a good starting point.

Of course I had to make several pin cuts , and add several wire’s , because I did not want to change any pin maps etc, I figured that was just asking for a lot of trouble…..

I did add 5.6k resistors on the [TB5] connections which probably are not needed.

I also decided to add a 560 ohm resistor + LED on [TB5] limit lines to show which limit I got stuck at.

Jogging etc working fine. Have not checked the probe out yet.

[TB5] 15-D10 = Y-Limit 13-reset = Estop 12-A5 = Probe 11-D12 = Z-Limit 10 -D9 = X-Limit

Life just gets in the way. I had purchased two Arduino boards a while back, but hadn’t made the time to do all the related ‘learning’ to get them working.

Anyway, I do want to make a shield that will get from the Arduino to my board, I want to throw in some opto isolation for inputs (limits, probe) and perhaps some LEDs so you can see which inputs are active (as you did!).

Maybe your interest will get me ‘off the dime’.

Thanks for your input!

Just connected the probe A5->12 and it works aok. I have noticed that your DB25 pin out diagram appears quite different from mine. You have D 15* A5(probe) I use TB5-12 , My Estop/Reset is TB5-13 ->Arduino reset pin, maybe I just don’t understand your diagram?

The Reset/A0 is software controlled, I don’t know how Arduino 1.1H handles it . That’s why I use Hard Reset.

Its been 5+ years since I’ve used the larger machine [ the one I’ve made the adapter for] I did 1 board MY CNC !

I’m using my own GRBL SENDER SOFTWARE written in Liberty Basic Pro 4.5.1. Its a little busy[lots of buttons] .

Its a work in progress , but working quite well, I think? I’ve added stuff and haven’t really tested it good since.. I made some PCB’s and RoadRunner on my smaller Bipolar moving table CNC before adding the changes, but the plotting window

appears correct, so I think all is good.

I just realized that the difference is probably due to how the pins were assigned when using mach 3 trial.

I carried same pin assignments over to ARDUINO UNO GRBL.

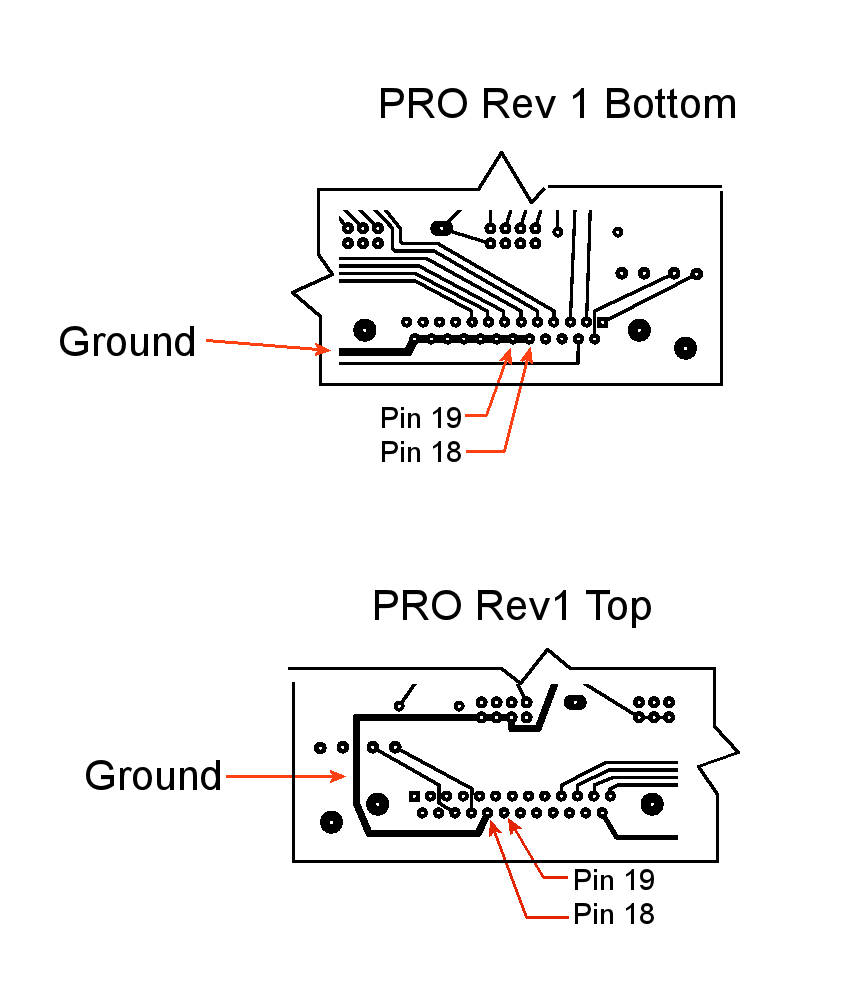

How easy would it be to free up Pin 18 and 19 on the CNC Pro card Rev 1.

Then I can possible use D13 and a hard reset for EMSTOP.

I’ve layed out a board as per your drawing and have and put PWM -D11 on pin 10 .

Single sided pc with several jumpers and limit led’s .

For the ‘inputs’ on TB5 (pins 10, 11, 12, 13 and 15) – how you configure your software determines what function these pins do. Could be a limit switch, a home switch or a probe (or whatever).

Regarding freeing-up pins 18 and 19 (assigned to ground as per the parallel port spec), you could do a hack. It is complicated as I use pin 18 to feed the ground thru from the bottom of the board to the top. You’d need hack some traces on the bottom and one on the top. I’ve included some detail to help you. Let me know if you need more info.

Looks like I need jumper around 19,20 to use them instead ..

Thx mike…

PS – Have you seen farmbot.org, it’s interesting, I have a xtra cnc pro card and 3 steppers,

now if I can figure out a simple interface from mega 2560 to cnc pro I may do some

experimenting……

Later….