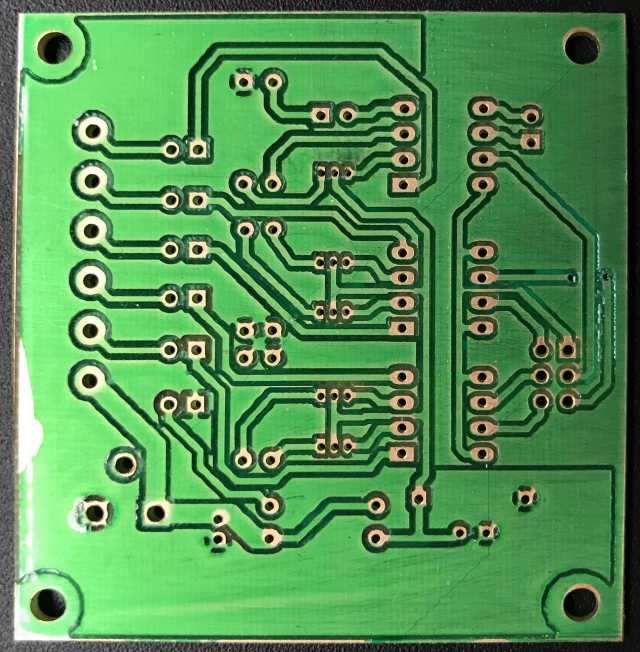

One of the things I like to use my DIY CNC router for is to make PC boards using the isolation routing technique. My latest prototype is Isolation routed PCB with solder mask for an opto isolator board to be used with the HobbyCNC Pro when the user experiences “false triggers” of their limit or home switches. I don’t encourage or use shielded wiring (see my post To Shield or Not To Shield (your wiring). But when nothing else works, this opto board will solve the problem.

This time I tried the addition of a dry film solder mask. This is my first attempt after some testing to figure out the time under the UV light (30 seconds in my case). It’s not quite perfect, but it is good enough for now. Holding the artwork down against the board with some glass will help, and having a black background below the board seems to help too.

looks well made good job where is the part list and the other side

I will provide the parts list and the other side (it’s a single-sided board) as soon as I can get time to put it together!

BrianV

Mr B,

My old controller has a Opto Isolater board should I use it and if so how do I wire it?

An opto board is typically used to electrically isolate your board from stray/bad input signals.

It would be of no help between the driver chips and the stepper motor, however.

An aside that I did not mention, is that an Opto board requires it’s own, isolated power source. If you just pull the 5 or 12 volts off another supply already in the box, then THERE IS NO ISOLATION, the whole purpose is defeated!

Regards, BrianV

Two parts to your question:

Should I use it

It wouldn’t hurt, but it may not be necessary.

How do I wire it

Not to be a wise guy – but it depends on the design of the opto board and

what you want to accomplish.

Reasons to use an opto board:

1) electrical isolation – to keep potentially hazardous or dangerous voltages away from your more delicate circuitry.

2) Voltage level shifting – to make that 24VDC signal into one that is compatible with digital electronics.

3) To eliminate ground loop issues – this is likely not an issue in a small, system like a milling machine.