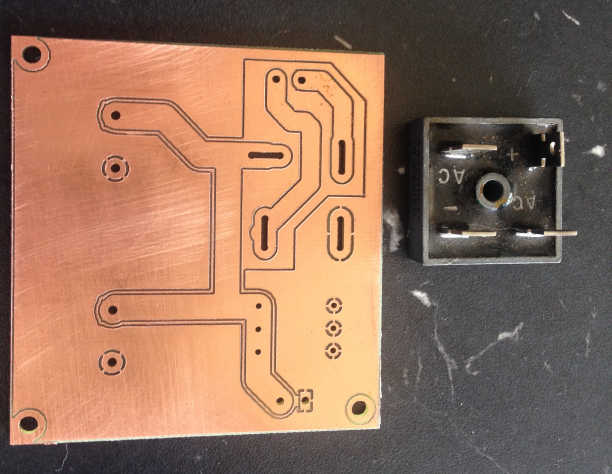

I needed a quick-and-dirty 36VDC unregulated linear power supply to drive some HobbyCNC boards on my test system. I wanted the bridge rectifier to mount directly to the PC board. The beefy bridge rectifier that I had in my stock was the type with the large spade-type terminals. I needed to mill slots in a PC board for mounting this bulky part.

Getting slots in the PC board took some digging. I designed the bridge rectifier footprint in KiCAD to have oval pads with oval holes, but this did not translate via the drill file into FlatCAM – only one round hole would be drilled.

To make the slots, I had to create a New Geometry ‘layer’ and add simple straight lines dead center of where I wanted the slots milled. FlatCAM would then just mill one pass, centered over that line. This required a third milling file – one for the bottom Cu, one for drilling and the third for the four slots.

Came out P E R F E C T! Next board will have some pretty fine geometry, squeezing traces between DIP pads. We’ll see. . .