Sometimes the answer is in the trash.

The background: while assembling a batch of HobbyCNC PRO boards, I was noticing how neatly the 23-pin driver chip dropped into the PC board. Then I had one chip with one lead, just one, slightly out of alignment. That particular chip was a lot more work to get it into the board.

Then I realized that how I’ve been shipping my kits with 3-or-4 driver chips dropped into an antistatic bag. This pretty much guaranteed mis-aligned pins on these driver chips after shipping. Not cool for my customers. Then it hit me. Rather than just throw-away the plastic tubes in which I receive the chips – how about I cut them into 3-or-4 chip-length “mini tubes” and ship the chips safely inside these new, shortened tubes.

The idea worked great, but trying to cut the tubes by using a ruler to measure the length each time was slow and inaccurate.

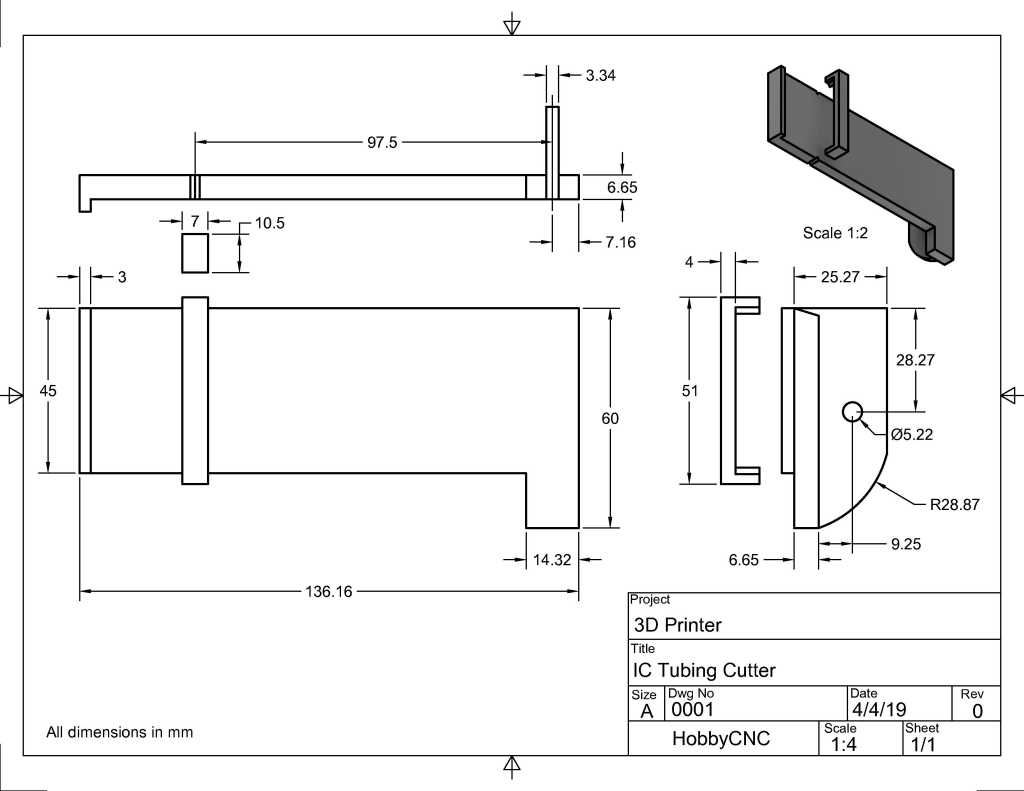

3D printer to the rescue. Now, I do love my DIY CNC machine, but sometimes you’ve got to add material, not remove it! I designed a platform to fit my old Sears Handi-cut tool.This tool has a removable lower platform that is held in place by a single screw.

I designed (Fusion 360) and made (MakerBot Replicator 2X) a platform with two stops (a fixed stop for a 4-IC tube, and a removable stop for a 3-IC tube. It works great, it’s fast, safe and accurate!

Damn I love CAD/CAM