Eagle and Autocad

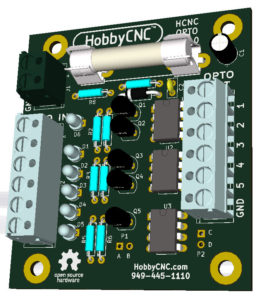

One thing I use my DIY CNC machine for is milling PC Boards (it’s technically called “isolation routing”). This is fairly fast, inexpensive, accurate and uses zero nasty chemicals.

I’d been using Eagle Schematic & PCB design software. Great product, works very well, I like it a lot.

Then Autodesk bought Eagle. I liked the idea of Eagle belonging to the Autodesk family (AutoCAD, Autodesk Inventor, Fusion 360 and many more). Autodesk is a great company, with equally great products.

But here’s the rub

Autodesk changed the licensing to a subscription model. So for the hobbyist, like me, I now have to shell out $100 USD per year. I don’t use it enough to justify this ongoing expense.

So I’m trying KiCAD. It’s free. This is good. It seems to have good community support. The core concepts are the same as any schematic capture software, but the implementation is different. KiCAD is different enough from Eagle that there is some learning involved. Nevertheless, I got a working schematic in and a PC Board designed. KiCAD has a built-in 3D viewer which I found to be super-cool.

So I’m trying KiCAD. It’s free. This is good. It seems to have good community support. The core concepts are the same as any schematic capture software, but the implementation is different. KiCAD is different enough from Eagle that there is some learning involved. Nevertheless, I got a working schematic in and a PC Board designed. KiCAD has a built-in 3D viewer which I found to be super-cool.

Next I need to export the Gerber and drill files into FlatCAD which will in-turn produce the necessary G-Code for milling. I’ve got my new Tapered-stub End-mill PCB Traces-isolation Bits from Think-and-Tinker/Precise Bits.

I’ll provide an update once I get a board milled.