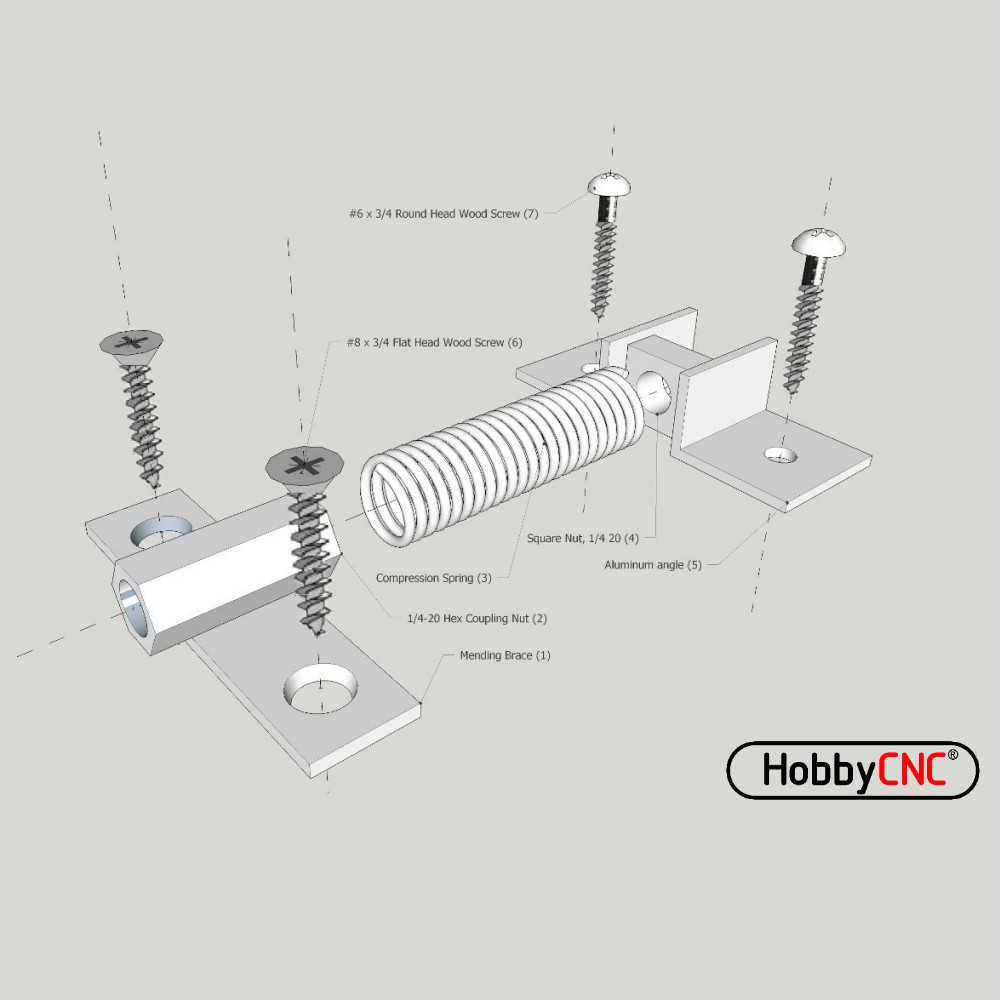

I developed a simple-yet-effective backlash preventer for my DIY CNC Router plans. The design uses a coupling nut with a flange welded on. This is fixed to the gantry.

A spring is ‘pinched’ between this coupling nut and a simple square nut. The square nut is prevented from turning by two L brackets.

I use my mill to isolation-route PC board prototypes. It works great. Except for one thing I didn’t consider. The Z axis goes up-and-down just a few tenths of an inch frequently. A lot of movement in a little range.

The failure point is to the threaded rod where it goes through the square nut. A lot of pressure in a small number of threads. My Z axis threaded rod stripped out, letting the tool drop into the PC Board and stay there, through the rapid moves and all.

Good thing I can quickly tell by the awful sound that something went wrong.

The PC board and the tool were shot, but the mill was fine.

My solution is to eliminate the square nut and L brackets, and just use a second coupling-nut-assembly.

This second coupling nut and flange are NOT attached to the gantry, and it is prevented from spinning due to the welded-on flange.

Works identically, but I’m hoping the LOTS of extra threads will save the threaded rod! I’ll let you know in another 5-or-so years!

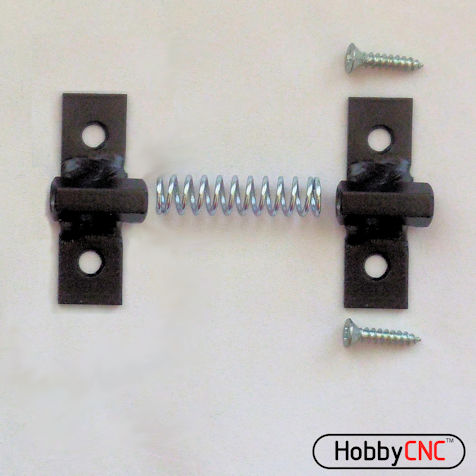

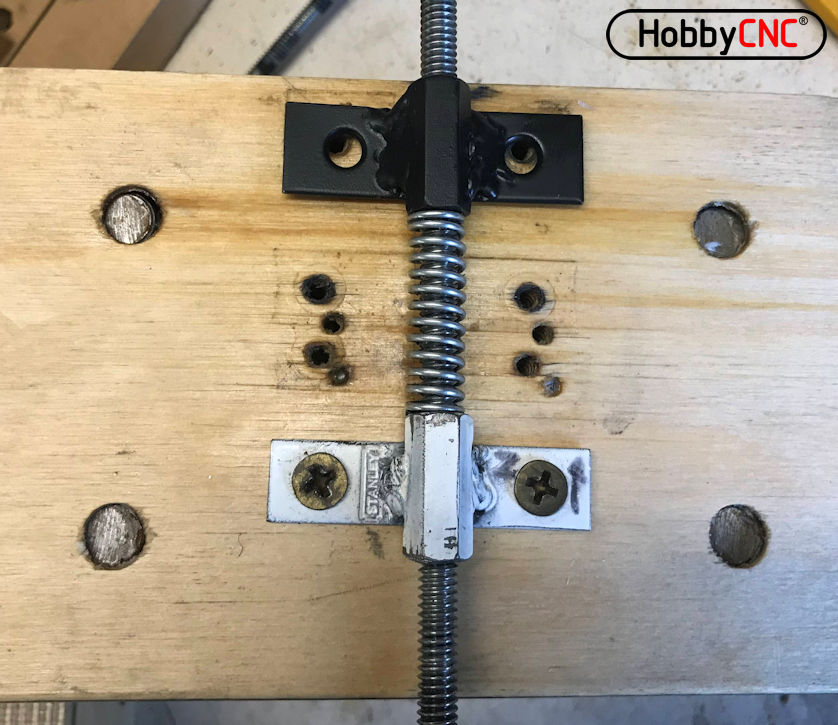

Here’s how it looks installed on the back of my Z axis gantry.

The bottom, white one is my original design from many years ago. Notice this one is screwed to the Z-axis gantry.

The top, black bracket, is holding compression of the spring, and it is NOT fixed to the gantry, but it is prevented from spinning by the flange resting against the back of the Z-axis gantry.

The net result is the Z-axis gantry is always being “pushed down”, away from the top, ‘floating’ coupling nut assembly.

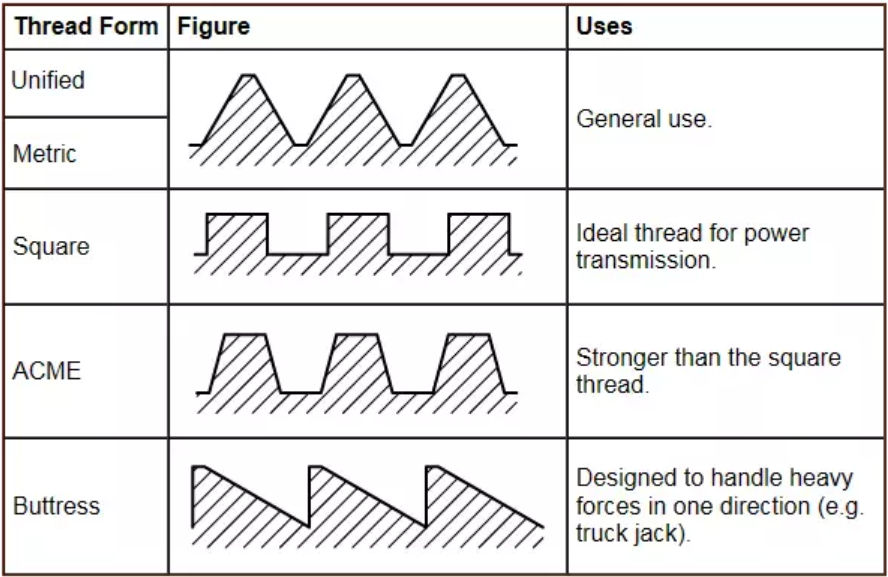

A quick note on threads. My DIY CNC Router is specifically designed to be inexpensive, and a such, uses ¼-20 all-thread threaded rod as the drive screw. This thread profile is shown at the top of the image.

However, this type of thread is not designed for the efficient power transmission. Ideally, you want an Acme or square thread, but these do tend to get pricey. Your call!