A BreakOut Board – a BOB for short, takes an input, typically from a computer or a ethernet/USB-to-parallel converter and splits up the signals into individual pins. These pins are then wired to individual stepper driver boards. Most stepper driver boards require two signals to make the stepper motor move – Step and Direction.

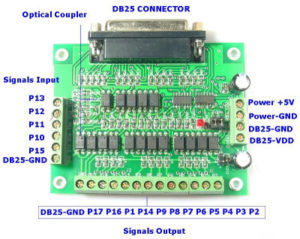

Figure 1 – a typical BOB

Also, like the board shown in Figure 1, there are opto isolators. These are to electrically isolate your computer from the stepper motor drivers. For most hobby installations, opto isolation for the stepper motor drivers is not necessary. There are cases where opti isolation makes great sense, like in more industrial environments where different machines at potentially different ground levels can cause havoc. I’ve personally seen this destroy unprotected electronics. See Ground Loop. It would be highly unlikely for a large ground potential to exist within a single piece of equipment.

Some BOBs can include LEDs on some of the lines – and this can be very handy during installation and debugging. BOBs can also include other features, but then they really aren’t BOBs anymore.

- Opto isolation (belt-and-suspenders)

- LED lites on some lines (maybe)

- Can possibly support more than 4 axis

- Looks impressive

- Opto isolation is not necessary

- Higher parts count – a whole extra board, components and LOTS of extra connections and wiring

- More complicated wiring

- Extra cost

Compare to HobbyCNC boards:

A BOB is not required for any of our boards. We put 3 or 4 drivers onto one board, and we route the wiring from the DB25 connector to the driver chips without the need of any additional circuitry. This provides a one-board solution with – zero extra wiring – for up to 4 axis – compared to 5 boards for a 4-axis BOB-based solution.

Figure 2 – typical wiring for a BOB with 4 axis.

Figure 2 shows the wiring for a typical BOB and 4 driver modules. It’s not rocket science, but as my engineer friend says “a key role of an engineer is to take out as much as possible, but no more”. If it can be done as good – or better – with fewer parts, less wiring, reduced complexity – then that is a win.

Of course, all that wiring and all those modules look really impressive, but that’s not why most of us are in this hobby!

As my daddy used to say “Keep It Simple, Stupid”.