Background

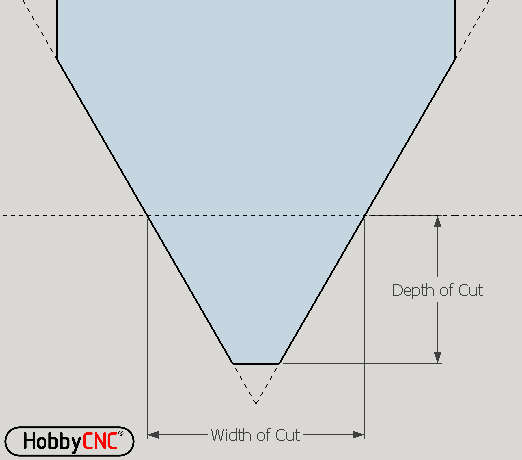

This calculator is for determining the width-of-cut of a “V” shaped cutting tool.

The deeper a “V” shaped cutting tool goes into the workpiece, the wider the path it will cut. And the bigger the angle of the cutting tool, the path can get pretty wide, pretty fast.

For PC Boards, your depth-of-cut only needs to remove the copper a little bit of the fiberglass underneath. And the copper isn’t very thick!

| Copper thickness | Inch | Mils (thousandths of an inch) | mm | Depth of cut* |

| 1oz | 0.00137 inch | 1.37 mils | 0.0347 mm | 0.002 in |

| 2oz | 0.00274 | 2.74 mils | 0.0694 mm | 0.004 in |

Source: pcbprime.com/pcb-tips/copper/

*Depth of cut is what I put into FlatCAM.

How the calculation works

In case you’re curious, here’s the dimensions and how the calculation works

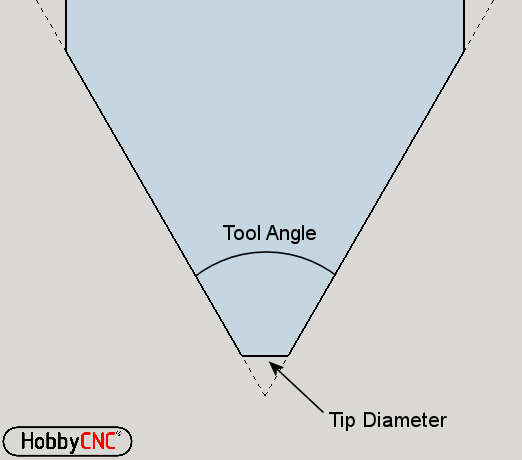

Figure 1 This it the tool angle. Typically 30°, 45°, 60°, 90°.

Figure 2 shows that the width of the cut is dependent on the depth of the cut. The deeper you cut, the wider the cut.

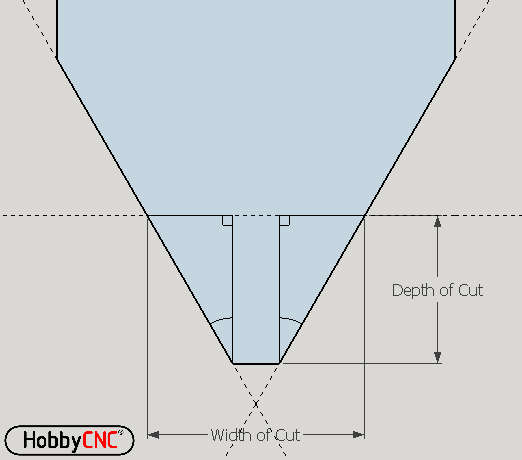

Figure 3 shows the addition of two right triangles. We know the angle (half the tool angle) and one side of the triangle (the depth of cut)

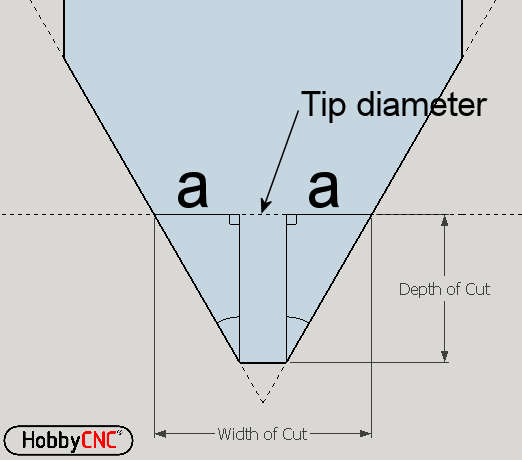

Figure 4 with the application of some basic trig (the TAN function) we can calculate “a“. Double that value and add the tip diameter and you’re set!