Sizing the power supply voltage and current is important to ensure your system performs at it’s best.

Voltage & Current

The stepper power supply MUST be capable of providing 50% of the TOTAL current draw of the steppers. A 2.5A stepper will draw 5 Amps! For example: 4 steppers rated at 2.5A will draw a total of 20Amps. Adequate fusing must be used on both the AC and DC side.

| Board | Min Voltage | Typical Voltage | Max Voltage | Suggested Current |

|---|---|---|---|---|

| PRO (3 or 4 axis) | 12VDC | 36VDC | 42VDC | 10A (4 axis) 7.5A (3 axis) |

| EZ | 12VDC | 24VDC | 36VDC | 7.5A |

Regulated or unregulated

Unregulated linear supply is fine. A regulated supply or a switching supply will also work well, but you’re paying a lot more for regulation you don’t need.

Typical Unregulated Power Supply Design

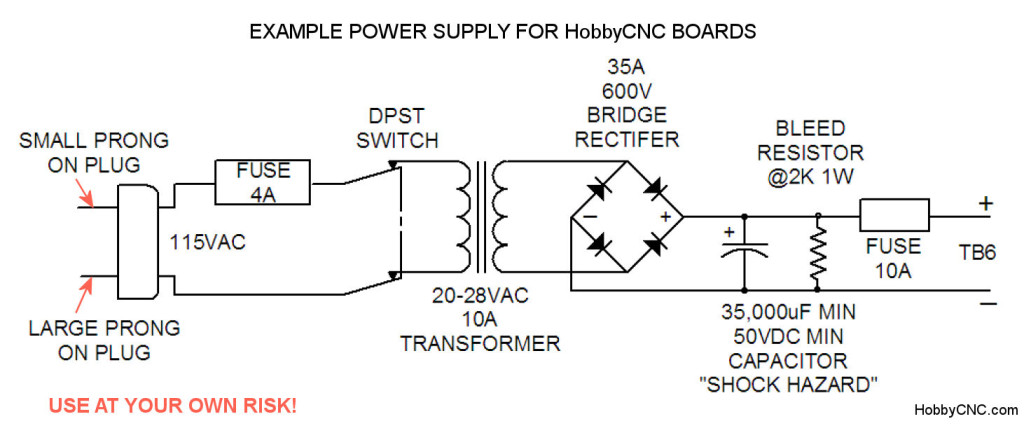

The circuit shown below should be adequate for most applications. It is the classic unregulated linear power supply.

A well ventilated metal or plastic enclosure is highly recommended. Secondly, be very careful not to short the terminals of the capacitor. A painful shock will result. I suggest several layers of black tape over the screw terminals before applying any power to it. The Bridge Rectifier will get warm, mount it accordingly. Lastly, builder and/or user of this circuit assume all risks and liability with it. It is presented here as a reference only.

Values given are adequate for the loads. Feel free to “upscale” them if you wish. For example, the 35,000uF capacitor, its OK to use higher values for sure in both capacitance and working voltage. I would NOT downsize the Bridge Rectifier.

The Bleed Resistor is required. Ok to use 2 4K 1/2W in parallel, or 3pcs 5.6K 1/2W in parallel.

Switching Power Supplies

I’m of mixed feelings about using switch mode power supplies (SMPS). I won’t use one for my motor drivers. Many SMPS are not designed to handle large inductive loads like stepper motors. However, I don’t seem to hear a lot of complaints about them failing either. There seems to be lots of cheap switchers available on eBay and other places (see my warning on The lowest price DIY CNC electronics isn’t always the best value). As my daredevil friend from Hawaii says “What could possibly go wrong?”.

SMPS are designed only to “deliver” power out to a passive load.

No ability for absorbing regenerating power from the Drive-Motor (Servo). When regenerating, the SMPS might be damaged!

SMPS are very sensitive to Inductive loads that “typically” create spikes, transients, surge voltage. In extreme cases the SMPS might be damaged!

The voltage regulation might be a disadvantage when regenerating. In regeneration/ braking, the load transfers power back to the power supply “enforcing” voltage increase on the terminals of the SMPS. When the terminal voltage exceeds the “set Voltage” of the SMPS, the close loop might fall “out of loop.” The recovery might last too long and at this point there is no output voltage from the SMPS. “No Power, No Servo!”

No peak current/ power capability.

The SMPS is designed to deliver continuously the rated power. It can’t deliver peak currents that are crucial for Servo operation.

Beware the cheap eBay Chinese switch mode power supplies

It might work. It might not. It might be safe, it might not. You are on your own here, proceed at your own risk.

What’s the difference? 36 VDC is 36 VDC, right? Not right. If your knock-off supply can’t deliver huge bursts of current as demanded to move stepper motors, or it can’t handle the back EMF from a stepper, then you might find slow speeds and low torque. Caveat Emptor.

Here’s a comparison between an ultra-cheap and a quality power supply by loneoceans published on Jan 18, 2015. All I’m saying is look at the difference in components and construction. Then again, you can by 2 of the cheapies for 20% the cost of a quality unit. Pick your poison.